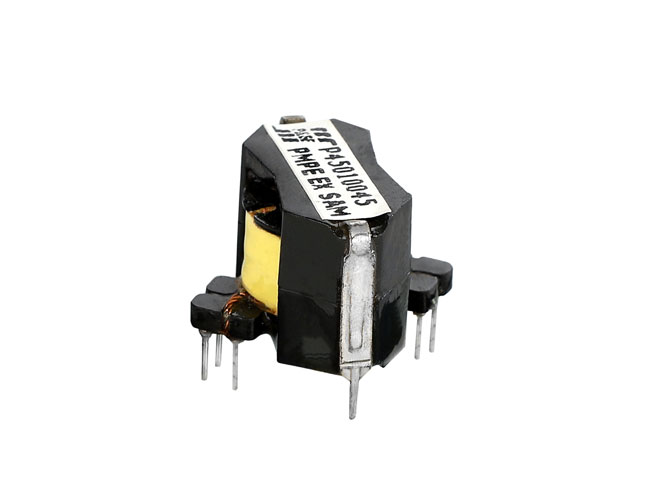

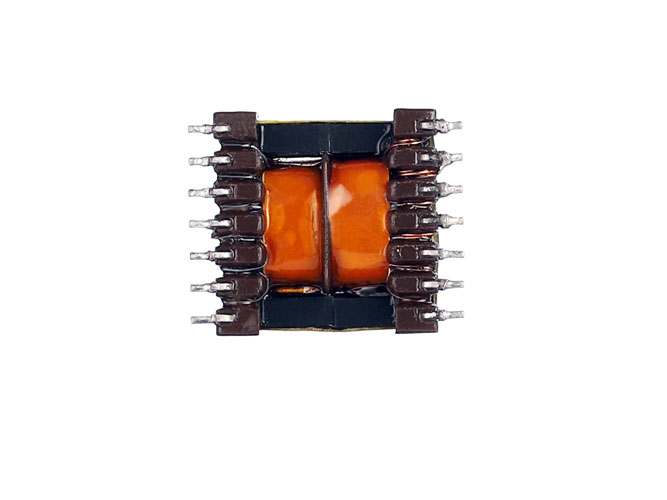

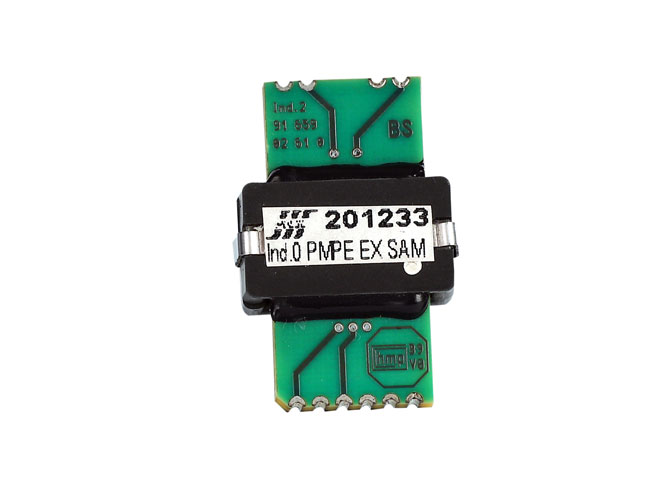

High Frequency Transformers

PMPE develops customized power transformers for 50/60 Hz mains rated from 1 VA to 20 KVA with single or multi outputs. Application includes Medical Systems, Isolation, Motor/Industrial Control, Power Control/Management, Test Systems, Defense and Stringent applications in size and shape

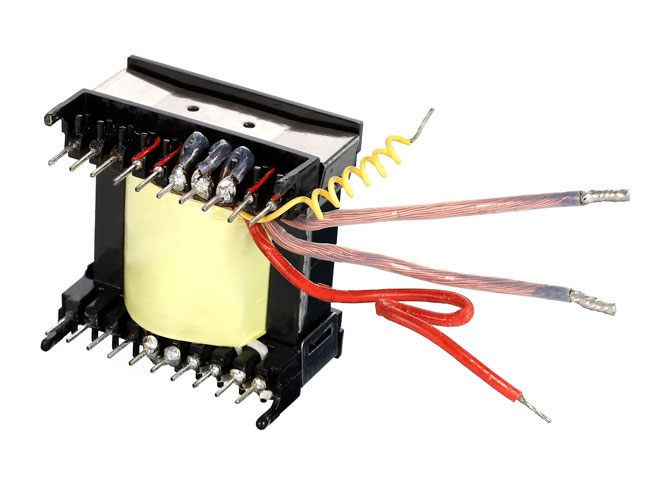

PMPE develops and produces customized power transformers for switched mode power supplies in all switching topologies, such as:

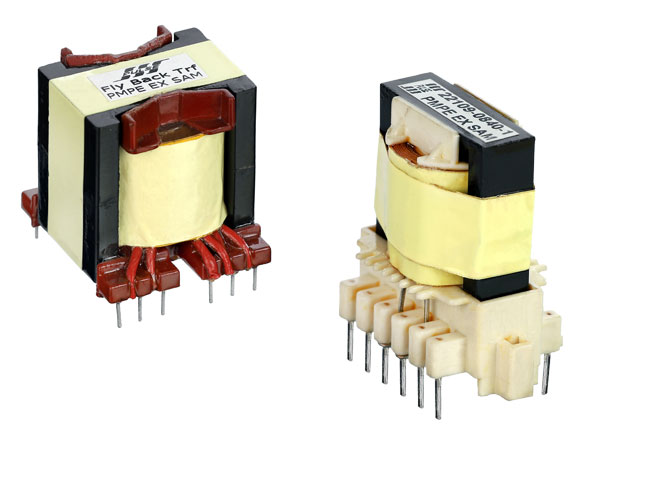

- - Fly back Converters

- - Forward Converters

- - Push-Pull Converters

- - Resonance Converters

- - Quasi Resonance Converters

- - Cuk Converters

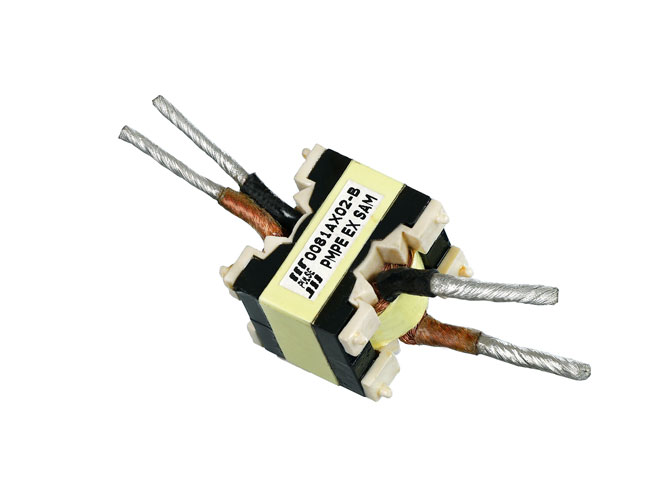

Technology: Parasitic characteristics of a transformer like leakage inductance, self / inter-winding capacitance, and thermal gradient grow with its mechanical dimensions. High Frequency transformers are optimized to create the smallest possible geometry to overcome effect of these characteristics. The optimizations are worked through to the highest possible density for both technical and commercial reasons. A major feature of electronic components for their operational reliability is freedom of its insulation system from partial discharge (Corona effect) PMPE develops and manufactures products with partial discharge- stable insulation systems up to 10 KV

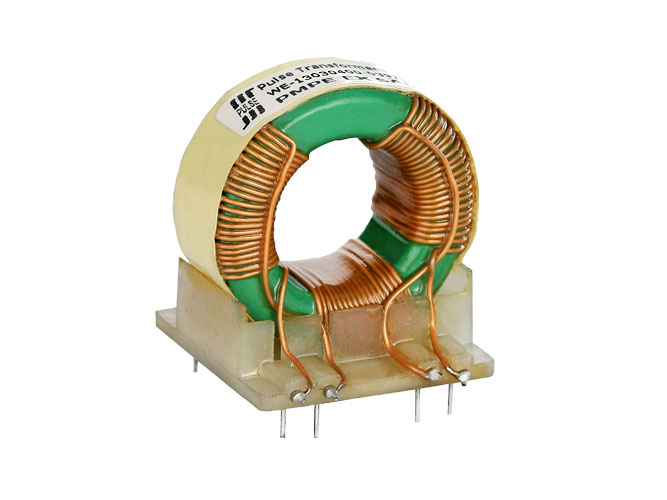

In order to achieve the desired technical characteristics, a wide variety of Core materials with innumerable geometries, conductors and designs are produced:

Core materials used:

- - Soft Ferrites

- - Amorphous Core materials

- - NanoCrystelline Core materials

- - Tape wound Si-Fe Cores

- - Tape wound Nickel iron Cores

- - Kool-Mµ and MPP Cores

Conductors Used:

- - Solid Copper wire with round and rectangular shapes

- - Litz wires (Copper) [ In house facility]

- - Copper Foil strips

Designs:

- - Bobbin core windings

- - Toroidal Core windings both open frame and encapsulated

- - Lead frame windings (Planner Transformers)