Overview

Decades of experience in designing and manufacturability of PMPE team ensures the quality and affordability one expects from an ISO certified company.

Value Chain Support

Whether the customer’s product life is two years or two decades, development team of PMPE has more than 46 years of experience in enhancing the Value Chains of the products manufactured by the company. As an ISO 9001:2015 certified company, PMPE products longevity is a direct reflection of its ability to provide value-add to our customers through all elements of their “product Life cycle Management”

Product Development

A collaborative design approach is followed for product development; to compress customer’s time to market and increase their “Return to Engineering Assets,” including reduction and elimination of trial and error or “what if” design iterations. PMPE Development teams work alongside the customer's, enabling him to focus on his value chain while they do likewise. Decades of experience in designing and manufacturability of PMPE team; ensures the quality and affordability one expects from an ISO certified company.

Prototyping

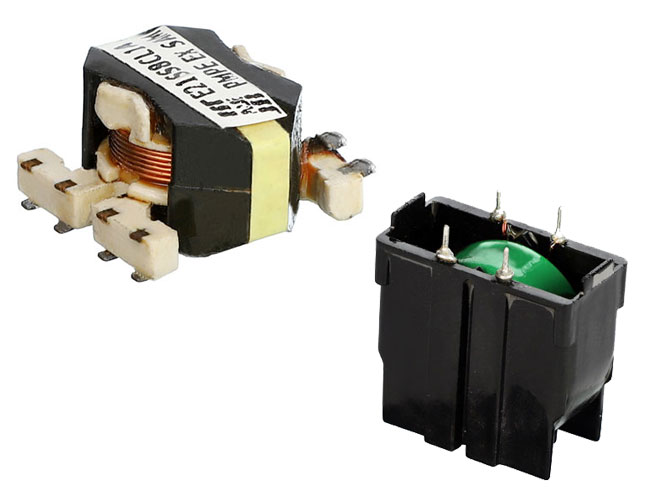

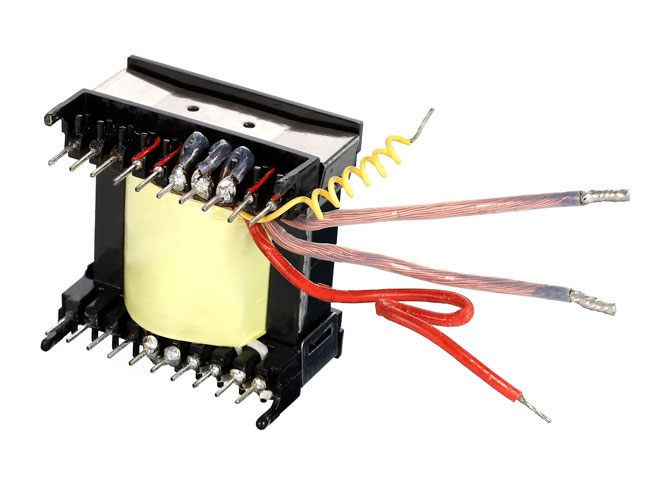

PMPE teams prototyping capabilities keep pace with the customer’s development team. PMPE application engineers assist customer in every phase of the product development process. From design feasibility, to design prototype, to engineering prototype, on to test and production, PMPE has the human and capital resources to ensure the customer has what he needs and when he needs.

Production

PMPE production facility is available to support the customer supply chain structure and objectives. In house development of special machines to manufacture difficult to make inductive components, Partner Company for plastic molding with modern tool room, in-house facility to manufacture Litz wire, with and without serve, for high frequency transformer application, enables us to achieve the best balance between cost and quality.

Production System

PMPE production system goal is “no surprises” and some important elements include:

- - Time-based Management

- - Work Teams with Visual Controls

- - Preventative and Predictive Maintenance

- - Single Piece Work Flow

- - First Article and Operation Traveler For Each Batch

- - Statistical Process Control

- - Production Parts Approval Process

- - Kanban Material Management

Partnership Programs

PMPE Production System is the foundation for partnership programs with our customer's which enables us to respond to their needs quickly and in innovative ways. It lets us work together to reduce not only product costs, but also many indirect costs such as inventory, engineering and quality administration, resulting in:

- - Lower total product cost

- - High Quality

- - Responsive delivery scheduling

- - On-time delivery

Work Environment and Work Culture

India is a tropical country where ambient can go as high as 50 degree centigrade. Providing a cool working environment on the shop floor though essential is not cost effective. Besides this the conventional central air-conditioning is unfriendly to nature. Mr. Baranwal who is a fervent lover of nature wanted solution which should provide cool working environment to its employees and also be very friendly to nature. Designing Geo-thermal cooling at such a small manufacturing unit was not an easy task. But with his perseverance and commitment to provide a cool working environment to his employees Mr. Baranwal implemented the Geo-thermal cooling which consumes only 3 KW of electricity and maintains 26 degree centigrade temperature for his 10800 square feet floor area. Now PMPE work environment is most comfortable, for its employees & management on the production floors using simple and nature friendly cooling system without much cost of electrical energy, an essential in-put for industries